At Fontijne Presses, we specialize in the development and manufacturing of high-precision hydraulic laboratory platen presses, trusted worldwide for polymer, rubber, composite, and other material testing and sample preparation. Our lab presses are designed for versatility and repeatability, enabling researchers and manufacturers to simulate real-world processing conditions with ease and precision.

Our presses are frequently used in combination with picture-frame molds, machined cavity molds, positive-type molds, or even without a mold. One key application area where no mold is used, is the preparation of thin polymer films.

By simply placing plastic pellets or powder directly onto the heated platens, users can produce uniform films ideal for analytical and visual applications.

Application examples

Thin polymer films are commonly used as samples in a variety of test methods across materials science, physics, chemistry, and engineering, where the Fontijne Presses lab presses are then used in combination with picture-frame molds, machined cavity molds, positive-type molds, or even without a mold. These method tests help evaluate e.g., optical, thermal and mechanical properties of the films. Here are some widely used test methods:

1. Optical Characterization

- FTIR spectroscopy: Identifies chemical bonds and functional groups in the polymer

- Visual inspection: Detection of contaminations, gels, degradations and other impurities

2. Thermal analysis

- Differential Scanning Calorimetry (DSC): Measures glass transition, melting, and crystallization temperatures

3. Mechanical testing

- Tensile testing: Measures tensile strength, elongation, and Young’s modulus of thin films.

Labmanual series

For applications like FTIR the thickness of the film is critical.

Films with a thickness of 50–120 micrometers can be reliably produced using the Fontijne Presses LabManual series, which is particularly well-suited for such precise and delicate film applications.

Step-by-step sample preparation procedure

The procedure is very simple:

- Material preparation

- The polymer is either in pellets or powder.

- It may be dried beforehand to remove moisture (depending on type of polymer).

- Mold setup

- The polymer is placed between two flat, polished plates.

- A release film (e.g., Teflon, aluminum, or PET) is used to prevent sticking.

- Heating

- The plates are heated to a temperature above the polymer’s melting point (for crystalline polymers) or glass transition temperature (for amorphous polymers).

- Typical temperatures range from 100°C to 300°C, depending on the polymer.

- Pressing

- Low force is applied to pre-heat / melt the polymer for a set duration.

- Increase the force to the required value and press for a defined time. This forces the polymer to flow and forming a uniform film.

- Cooling

- Without pressure: take the sample out of the hot press to passively (by air) cool down.

- With pressure: the system is actively (water) cooled while maintaining pressure to solidify the film and prevent warping or bubbles.

To prevent adhesion, aluminum foil (resulting in a rougher film surface) or PET foil (producing a smoother finish) can be used as release layers.

Consistent results with the Fontijne Presses lab presses

For companies processing increasing contents of recycled polymers in a (blown) film extrusion process, knowledge about contamination is essential to define the correct sieves used in the filtration system of the extruder.

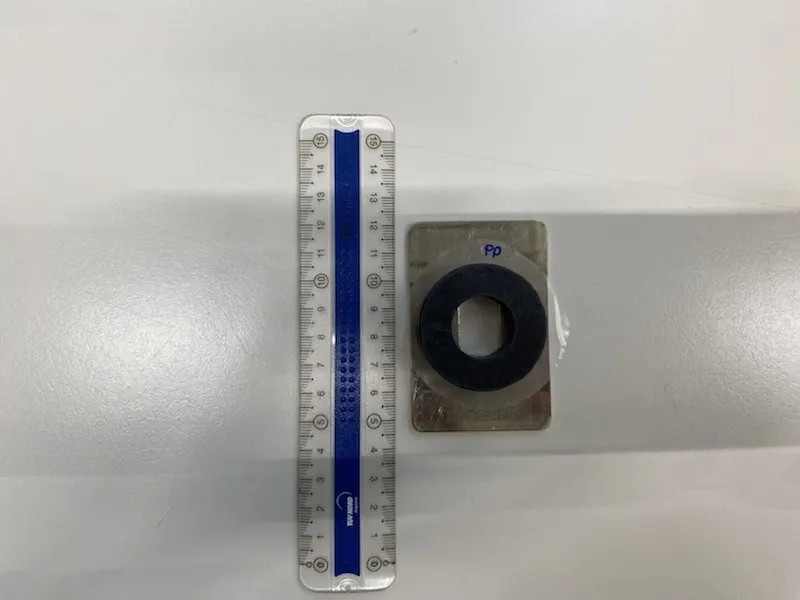

An easy and effective way is using a pressed thin film for visual detection of contaminations, gels, degradations and other impurities. For blown film applications, the pressed shim is heated and blown to simulate the actual film blowing process.

The images in this article show key components and outcomes of the process: film sample holder, the press setup, and the resulting films—demonstrating the versatility and consistency achieved with Fontijne Presses laboratory presses.