Recently, we have been challenged by one of our customers to do pressing trials with glass using our hydraulic platen presses.

Bonding of laminated glass

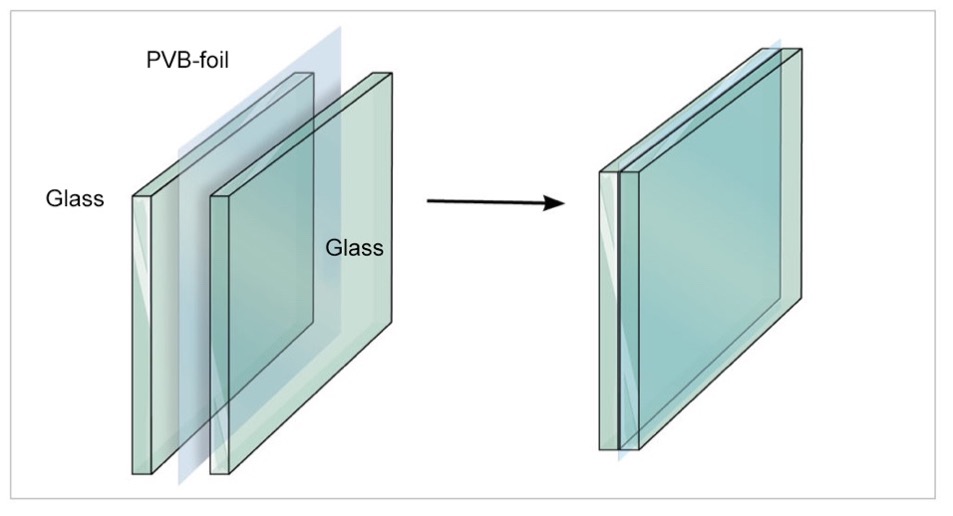

The challenge consisted of bonding PVB (PolyVinyl Butyral) interlayer film between 2 panels of glass. Laminated glass is a type of safety glass that holds together when shattered and that is commonly used in applications that require strong binding, toughness, and optical clarity for example in the automotive and architectural fields. The bonding process takes place under high heat and pressure conditions.

When laminated under these conditions, the PVB interlayer film becomes optically clear and binds the two panels of glass together.

The main three beneficial properties of the interlayer film providing to the laminated glass panes are:

- distributing impact forces across a larger area of the glass panes increasing the impact resistance of the glass

- binding the resulting fragments if the glass is finally broken

- absorbing energy and reducing penetration by the impacting object.

Besides the safety and security benefits, laminated glass also has decorative applications for example the blue or green “shade band” at the top edge of many automobile windshields.

Using the Fontijne lab press for pressing of interlayer films

Thanks to the LabEcon laboratory press with the integrated ProView software, the user has full control over the process of pressing and the parameters used to reach the end result. By optimizing the heat and pressure parameters, a program for pressing samples meeting the customer requirements can be created. A second thermocouple can be used to read out the actual glass pane temperature during the trials.

Fontijne Presses laboratory presses are used for Research & Development purposes but also for Quality Assurance and/or Control during the production of the resins as well as the interlayer films.

Please reach out to us and learn more about our platen presses capabilities.