Lignitec is an ambitious and forward-thinking start-up dedicated to developing biocomposites made entirely from natural fibers and natural binders. While conventional wood composites often rely on synthetic resins or glues, Lignitec is committed to creating materials that are fully biobased and free from fossil-derived chemicals.

This not only makes their products more sustainable but also safer, healthier to use, and easier to recycle.

The challenge: Combining strong material performance with sustainability

Conventional composites use synthetic, fossil-based resins or adhesives that are harmful to both people and the environment. These materials are difficult to recycle and lead to high CO₂ emissions when incinerated.

What sets Lignitec apart is their reverse engineering approach to plants. By combining natural fibers with a natural adhesive, they literally take plants apart and put them back together again. Based on their analysis approach of raw materials like wood, hemp, or flax down to their base components — cellulose, hemicellulose, and lignin — they can recombine these elements in new bio-composites with the desired material properties.

Lignitec’s biggest challenge was to combine environmental friendliness with high material performance. They aimed to develop a bio-composite that was:

- 100% biobased and free of synthetic additives

- Strong enough for constructive, interior and exterior applications

- Water-resistant, without using synthetic coatings or adhesives

- In the future, suitable for load-bearing construction applications

Water resistance was particularly difficult to achieve. Natural materials are typically sensitive to moisture — and without synthetic resins, achieving true water resistance is a complex technical challenge.

Breakthrough enabled by the Fontijne Presses laboratory press

The breakthrough came when Lignitec gained access to the right raw materials and was able to immediately test them using the Fontijne Presses laboratory press.

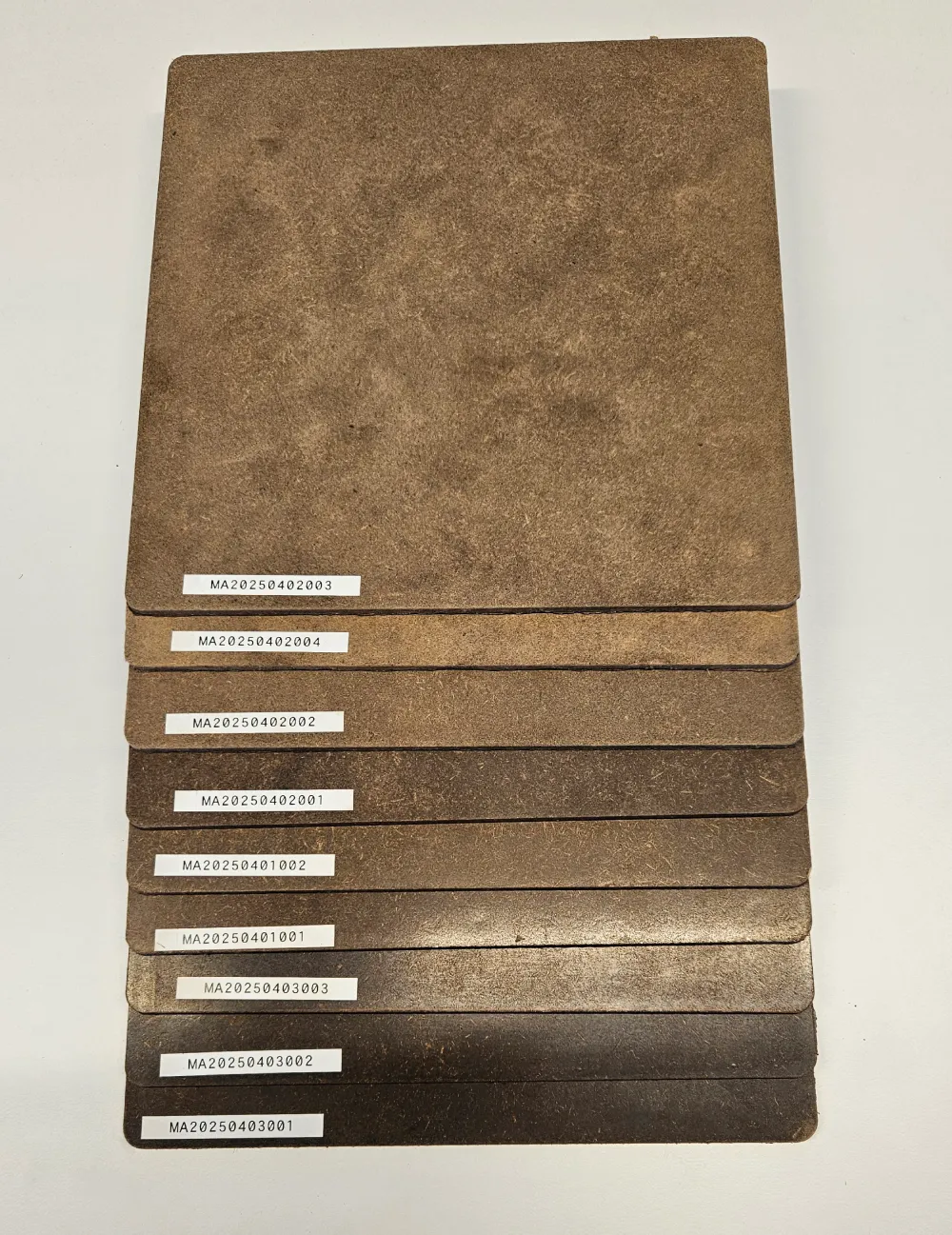

Lignitec makes intensive use of the Fontijne Presses press to develop, test, and refine their biocomposites samples in 300 x 300mm format.

The immediate availability of the press allows them to test formulations and produce samples with small batches under controlled pressure and temperature. This significantly shortens development time and led to the first successful biobased, water-resistant panels.

Accelerated innovation process

The lab press plays a central role in Lignitec’s daily development work:

We can literally think of something — like ‘would this work, or that’ — and then immediately test with the press and improve it.Henk RustingCo-founder Lignitec

Thanks to this flexibility, they can create prototypes in hours rather than waiting days or weeks for external testing setups. This leads to:

- Better control over process parameters

By varying parameters like pressure, temperature, and press duration, they can quickly and cost-effectively test new formulations — producing high-quality “samples” for mechanical and physical testing. - Shorter iteration cycles

Because they have their own lab press, Lignitec can immediately test and validate new ideas. This includes experiments with a variety of natural raw materials such as hemp, flax, miscanthus, wood fiber — and even tomato stems. - Reproducibility and accuracy

Precise control over temperature and pressure ensures that tests are consistently reproducible, reducing human errors, and allowing reliable material comparisons.

Results and impact

The Fontijne Presses lab press has proven to be a critical investment for Lignitec, enabling the development of:

- Water-resistant biocomposite panels for kitchens, interiors, and façade applications

- Strong, dimensionally stable materials produced without synthetic adhesives

- Full integration of natural fibers such as flax, hemp, and wood fiber using natural binders

From prototyping to full-scale production

Lignitec is now working on scaling up to larger panel formats and industrial production. The expertise developed using the lab press forms the foundation for this next phase.

Upcoming applications are focused on the interiors market and the construction sector, including circular façade panels, wall systems, and in the future load-bearing structural elements.

Conclusion

The Fontijne Presses lab press has not only accelerated Lignitec’s testing process — it has made real innovation possible, such as the development of biobased water-resistant materials that were previously thought impossible without the use of synthetic (fossil-based) adhesives.

Thanks to the Fontijne Presses hydraulic laboratory press, Lignitec now has a direct pathway from concept to product.