Understanding the critical need for streamlined and automated production cycles, Fontijne Presses has engineered the Cassette Cooling Press to cater to industries where rapid cooling is a prerequisite for material testing and high-throughput processes.

This cutting-edge solution is set to become a game-changer, particularly where reliable and reproducible test results are paramount.

Unique design

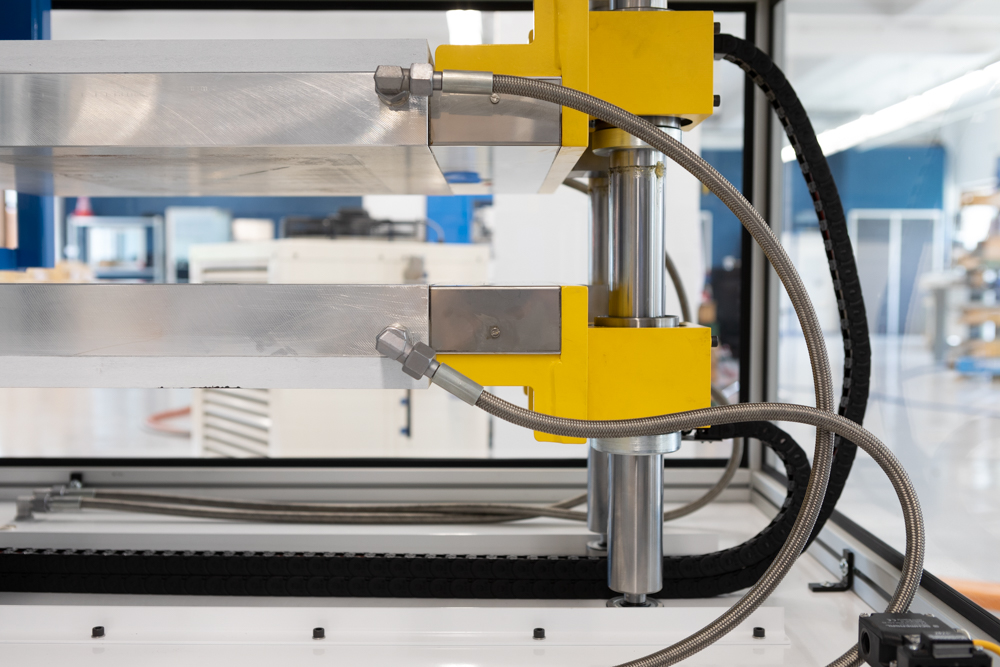

What sets the Cassette Cooling Press apart is its automatic control system and a distinct design that places integrated fast cooling at the forefront. Unlike traditional methods, which involve a time-consuming hot/cold/hot process, this laboratory press ensures continuous heating of the press platens while simultaneously cooling the cassette platens. This not only enhances efficiency but also significantly reduces energy wastage.

Have a look at the working of this innovative press via this video:

How does the press work?

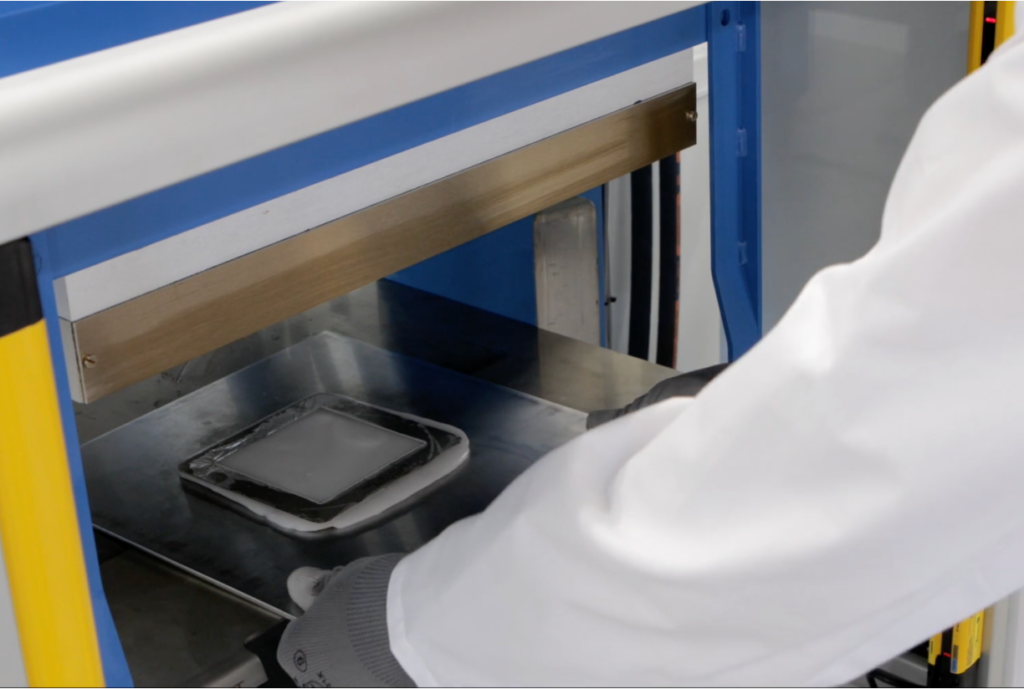

The cooling sequence, an integral part of the fully automated cycle, begins with the opening of the press and placing the sample in the middle. A transfer unit is then employed to seamlessly exchange the heated platens with the cooled cassette platens, initiating immediate cooling. The Cassette Cooling Press achieves remarkable cooling speeds of up to 250 degrees Celsius per minute, depending on the conditions.

Importantly, the cooling platens remain cold, allowing the operator to swiftly remove the current sample and introduce the next one. This not only saves valuable process time but also ensures that the hot platens remain hot, allowing for a new cycle to commence without delay.

Luc Pattyn, Sales and Marketing Director at Fontijne Presses, explains:

“The Cassette Cooling press is a testament to our commitment to advancing technology in material testing. This newly developed press as part of the LabPro series reflects our dedication to providing efficient and reliable solutions to industries that demand efficiency, precision and speed in their processes.”

Overview key features Cassette Cooling lab press

- Continuous heating and cooling: Our unique design allows the press platens to be continuously heated while cassette platens are continuously cooled, eliminating energy wastage efficiently.

- Fast and efficient cooling: Achieve remarkably fast cooling speeds of up to 250 degrees Celsius per minute, ensuring precise and reliable test results.

- Fully automated cycle: The cooling sequence, part of a fully automated cycle, involves opening the press, placing the sample, and using a transfer unit to seamlessly exchange heated platens with cooled cassette platens.

Main benefits of the Cassette Cooling press

Companies engaged in research and development, quality control, and production testing will find the Cassette Cooling Press indispensable, setting a new standard for efficiency and reliability in material testing and sample preparation.

Contact us today to find out how the Cassette Cooling Press can revolutionize your testing processes.