About Arceon

Arceon was founded in 2018 with the vision to empower revolutionary technology advances by developing materials (Ceramic Matrix Composites – CMCs) with unique properties such as extreme heat resistance, superior durability and reduced corrosion levels, among others.

Offering a wide range of customized and comprehensive solutions, enhancements and innovations on existing as well as future challenges, the company is currently active on the aerospace, defence, and refractory global markets.

Arceon Novel Elements develops low cost, lightweight and high temperature (>1200°C) stable ceramic composite materials and products. Arceon’s focus is to make a diverse product portfolio with different ceramic composite material variants. Arceon can manufacture components from woven fabrics, prepregs, ultra-high modulus & PAN based continuous and short/chopped fibers with a thickness range of 0.3 to 100mm.

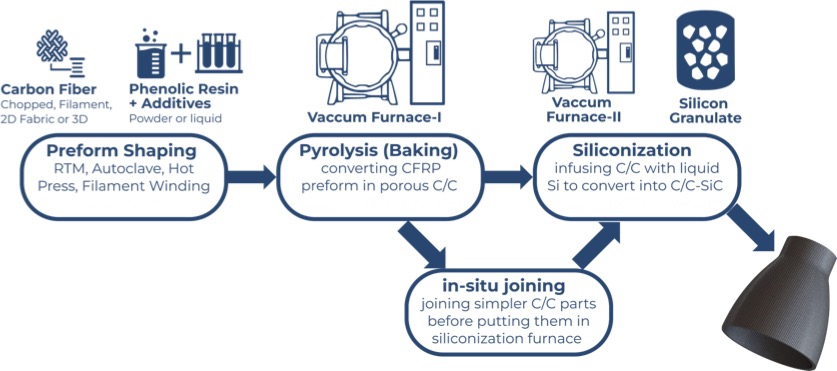

Development and manufacturing process of ceramic composites variants

Process steps

1. Shaping

The raw materials i.e., fibers and polymer resin are molded into the desired dimension of the product. The resin is solidified/cured under appropriate combination of pressure and temperature to achieve a stiff component.

2. Baking

This process takes place under an inert environment at 1000°C. The volatiles from the polymer resin leave the component making it a highly porous carbon/carbon product.

3. Infusion

The infusion of silicon takes place under vacuum at >1500°C. The silicon granulates melt and infuse inside the component due to the capillary action of the pores. The silicon reacts with the carbon left by the polymer during baking. Thus, resulting into a carbon ceramic product (carbon/carbon-silicon carbide).

How Fontijne Press laboratory press assists the production of sounding rockets

Solid Rocket Motor (SRM) Nozzles

Sounding rockets are one or two stage solid propellant rockets used for probing the upper atmospheric regions and for space research. The SRM nozzles are generally used in Sounding rockets.

The “Shaping” stage is one of the most important steps for determining the properties of the material after the “Infusion.” The Fontijne Presses LabEcon 600 ProView laboratory press allows the team at Arceon to achieve uniform pressure over the mould of the product, which ensures a high-quality component. To ensure the safety of the working personnel, the laboratory press is equipped with exhaust connection and closed processing zone so that the volatiles from the resin does not contaminate the lab space.

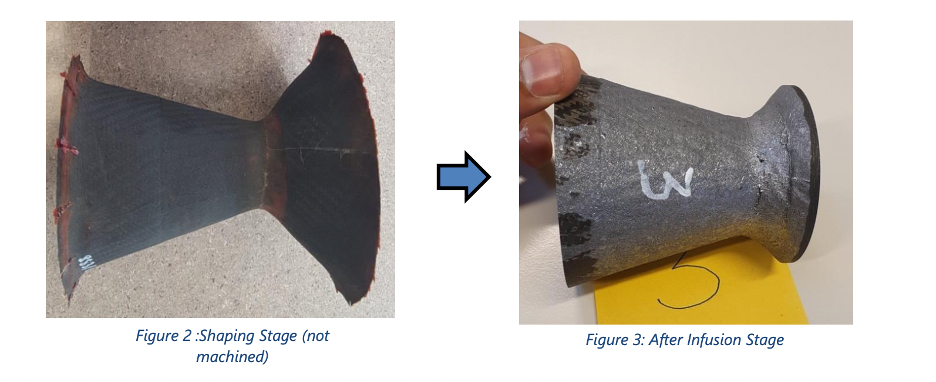

Figure 2 shows the raw part after the Shaping stage. Prepregs are wrapped on a mould and an autoclave process follows to achieve the desired shape. After testing the nozzle, it was concluded that the nozzle could withstand 5 times the operational load.

Hence, Arceon is able to manufacture a nozzle using chopped carbon fibers (low-cost raw material). The processing of chopped fibers is not possible through Autoclave technique, but thanks to its extended capabilities the laboratory press from Fontijne Presses enables the team to make this possible.

The overall cost of running a hot press is also lower than an autoclave which reflects in the end product cost. All of this contributes to making an attractive proposition offer for the Arceon’s customers.

The specifications and features of the LabEcon 600 lab press:

- Integrated hydraulic unit

- closing force 600 KN

- 2 electrically heated steel plates of 400 x 400 cm

- temperature of 300 C

- Cooling incl. airblow

- One daylight of 300 mm