About AGC Chemicals Europe

AGC Inc. is a multinational corporation and one of the world’s largest manufacturers of glass, electronic displays and chemical products.

As a world-leading manufacturer of fluoropolymers and fluoroelastomers, the European subsidiary, AGC Chemicals Europe, has been providing solutions specifically aimed to create a sustainable future.

Understanding the versatile use of fluoropolymers and fluorochemicals

Fluoropolymers and fluoroelastomers are unique materials with specific properties which lend themselves to many industries. Thanks to their high chemical and temperature resistance, and excellent electrical properties, these materials are go-to materials for a wide range of applications from aerospace, and medical to green energy amongst others.

Climate change is one of the largest issues of our time. Within Europe there is a large push to produce and provide green energy solutions to address these climate change issues.

Hydrogen power is one of the solutions that is playing a large role addressing these issues.

Currently AGC Chemicals Europe offers many products which play a part in hydrogen power and the green energy transition. Much research is currently being carried out into the production of hydrogen; this is required to produce more efficient systems for the generation of hydrogen.

It is therefore essential to produce high quality Catalyst Coated Membranes (CCMs) using AGC Chemicals Europe fluoropolymers to generate hydrogen during proton exchange membrane (PEM) water electrolysis (PEMWE) which will accelerate the green energy transition.

HEAL – Advancing hydrogen applications

AGC Chemicals Europe operates a technical service center located in Amsterdam to provide technical support to a wide range of products and customer projects.

In March 2023, the Hydrogen Energy Application Laboratory (HEAL), based at the Amsterdam Science Park, was opened to improve the support to customers and users of FORBLUE™ membranes and ionomers for water electrolysis.

The establishment of HEAL is a response to increased demand for testing, characterisation, and qualification effort within the industry. Specific capabilities cover in-situ and ex-situ proton exchange membrane water electrolysis testing to assess performance, endurance, process optimisations, and failure analysis, advancing the technical readiness of membrane solutions.

Part of this technical readiness is to produce CCMs following customers specifications that prove the capability of the FORBLUE™ membranes during specific conditions.

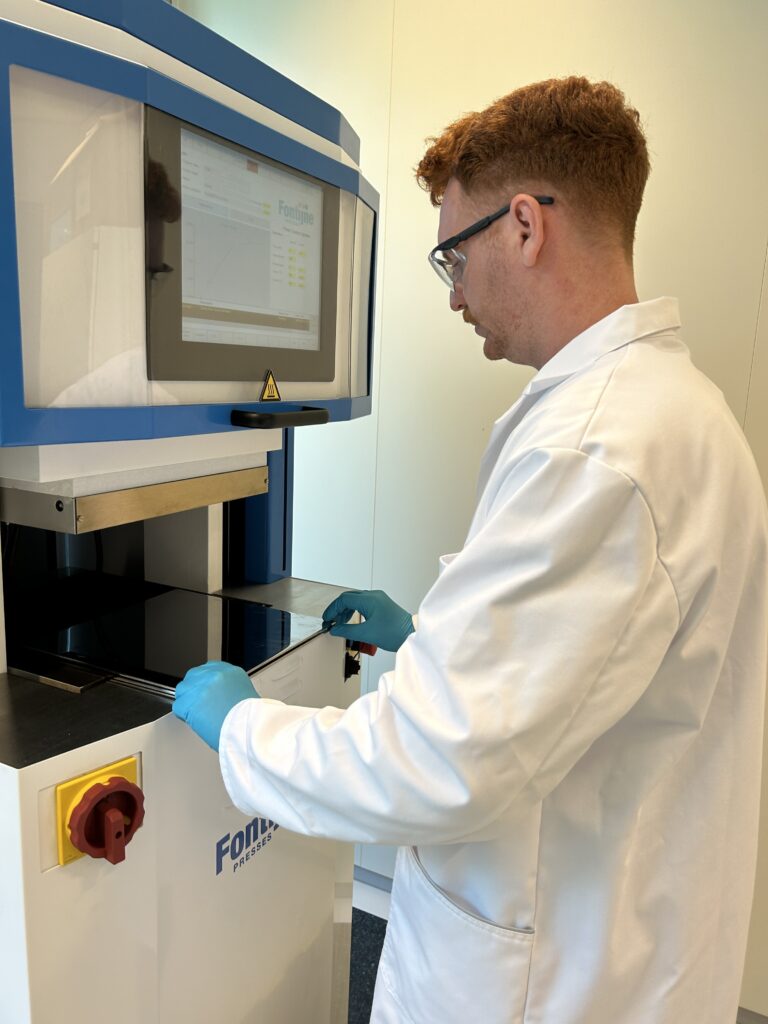

To produce CCMs, catalyst must be applied to one of the FORBLUE™ membranes using AGC Chemicals Europe ionomers. During this process uniform heat and pressure application is essential to creating high quality CCMs.

In order to do so, AGC Chemicals Europe wanted to have in their lab a press from Fontijne Presses that can easily apply uniform heat and pressure to their membranes.

Elevating hydrogen membrane processing with the LabEcon press

In the development of catalyst coated membranes, specific stages in the process are prone to errors and therefore pose potential challenges. Having detailed data on pressure distribution, temperature control, and adherence to the operating parameters is crucial. This information allows for swift identification of the root causes of failures or production errors.

Fontijne Presses LabEcon laboratory press enables AGC Chemicals Europe to solve their challenges by being able to apply uniform pressure and temperature across the CCM surface with ease. By ensuring that the press operates consistently with the same specifications as the previous run, concerns about process issues downstream are alleviated, enabling a faster response to any issues that may arise.

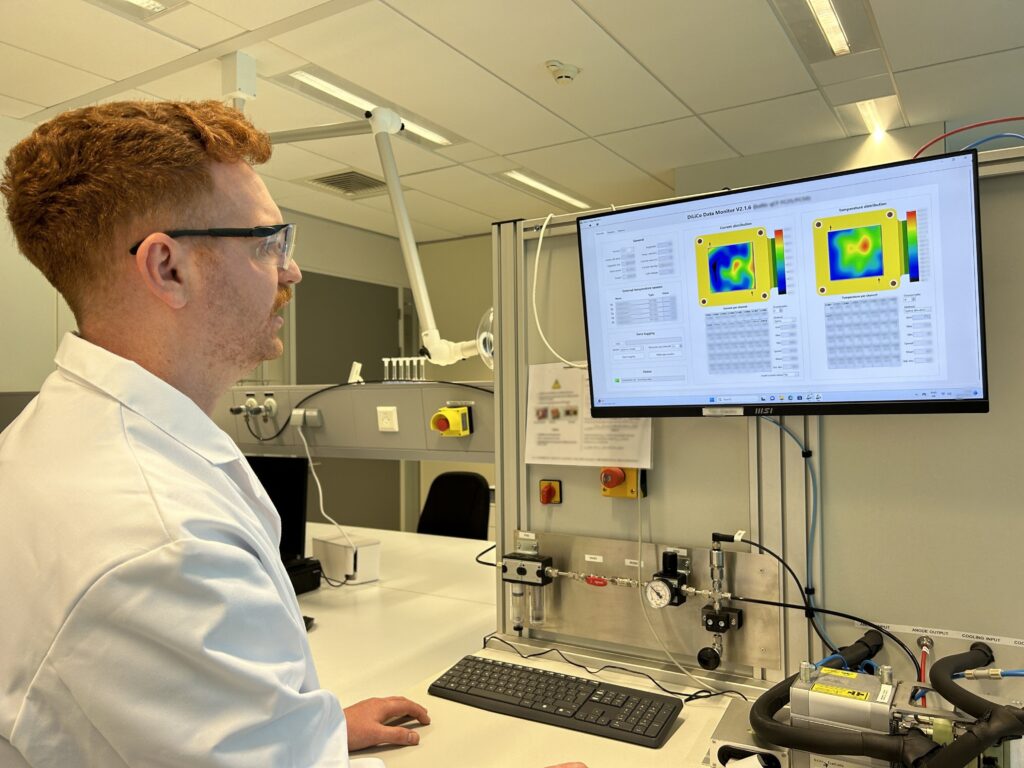

The monitoring system integrated into the press provides invaluable data to monitor the processes in the lab and help pinpoint any potential issues during production.

Besides that, Fontijne Presses offers the benefit of being a local European supplier, with highly customisable and cost-effective options ensuring that the presses can be used not only for the purposes they were purchased, but also for any expansion plans in the future.

The scripting is really nice, and the visualization is a lot more than any other tools on the market; so quite impressive to work with. Together with the local support offered, the price and the customization options made possible on the press – were the decisive factors to purchase the press for the labs in Amsterdam.Peter MinshalHydrogen Application Scientist working in the HEAL laboratory explains more why the company chose the press

The results

The LabEcon press purchased for the HEAL laboratory meets the specifications of temperature of max 400 degrees and pressure of 600kN. The press is used mostly to enhance production and quality control through programmable recipes, streamlining the creation of uniform CCMs and minimizing downtime. This efficiency boost aids in promptly identifying and addressing issues during the process.

Additionally, the press is expected to elevate AGC Chemicals Europe’s product quality by addressing challenges in CCM production, particularly those related to heat and pressure distribution affecting hydrogen production.

Peter Minshall talks about the results achieved with the LabEcon press:

“The outcomes have been consistently positive, we haven’t experienced any setbacks in our process, despite its inherent experimental challenges and a typically high failure rate. This positive outcome is a significant boost for the team. The method setup was effortlessly accomplished in a single attempt, and we’ve encountered no issues since its implementation.

Employing the same recipe consistently, we monitor pressure across each membrane once the initial setup is complete”.

Fontijne Presses: a trusted partner

Peter Minshall mentions about the collaboration with Fontijne Presses:

Fontijne Presses has been very responsive to questions and provided sound advice for our applications. The competitive price and ease of use of the equipment are both important to AGC Chemicals Europe, and in these two areas Fontijne Presses has a very good turnaround. The safety aspects of the equipment are also very important, Fontijne Presses was always happy to answer and offer solutions to ensure safe operation with our lab.

AGC Chemicals Europe would recommend the Fontijne Presses laboratory presses to other companies, as the solution offered at a very competitive price has helped AGC Chemicals Europe in their mission to open HEAL.