The 5 most important factors to consider when buying a platen press

April 26, 2021

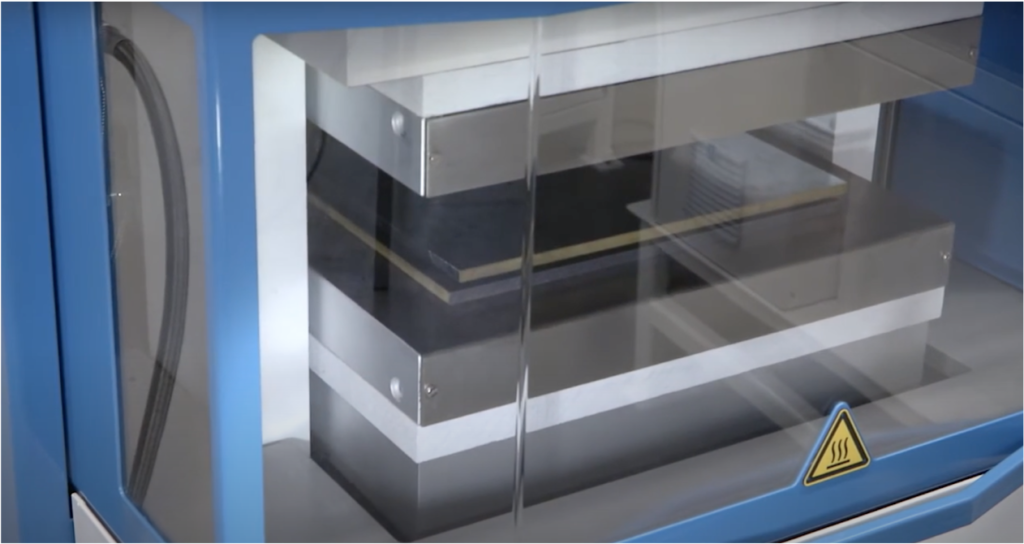

In recent years, laboratory platen presses have found more and more applications. Each sample has a combination of best settings that need to be taken into consideration for sample preparation for the optimization of the results of the analysis.

Once the decision has been taken to purchase a lab press, there are still quite a lot of questions to be answered before finding the right press. In this blog, we will discuss the factors you have to take into consideration when purchasing a new platen press.

How to select a platen press

(1) Technical performance and customization of the platen press

The more info we receive about the process cycle and the materials that are used for sample preparation, the better we can guide you to finding the best suitable press according to your requirements.

Let us know the required maximum temperature (e.g. 200°C, 300°C, 400°C or higher), the minimum and maximum required closing force (e.g. 50 kN, 300 kN, 600 kN, 1000 kN or more), the mould or platen size (e.g. 320 x 320, 400 x 400, 500 x 500, other sizes), and we are able to make already the first selection.

Is cooling required for your process? Or do you want to cool down the press actively to ambient temperature before leaving the lab? Do you need a multiple stage recipe or is a single temperature and pressure control sufficient? Is data readout or data transfer needed? Having the answers to those questions, we can select the optional features and suitable software.

Fontijne Presses offers extensive and in-depth customising options, to make sure that the press will meet all requirements. Are you working with moulds that are thicker than our standard daylight opening? Do you want to test under vacuum conditions? Let us know and we will work out a suitable solution.

Be aware of the fact that you need reliable samples: the outcome of analyses can only be compared when your specimens are consistently well-made. So pay attention to the uniform temperature distribution and the parallelism of the heating platens. The special design of the Fontijne platen press results in remarkably high parallelism of less than 0,1mm under all conditions (warm/cold, no pressure/full pressure) according to NEN-EN-ISO 1101.

(2) Operation of the press

Our user-friendly Programmable and ProView control systems enable automatic control of the press cycle and come with the following features and setting options: temperature and pressure control, heating and cooling ramp functions, pressureless preheating, graphical representation of the process, data recording and USB export options and different user access levels. Using the preset builder, lab technicians can easily build and store up to 999 press recipes. Selecting and starting a preset will start the process cycle automatically and will execute all program commands and events.

Our manually operated presses are equipped with digital temperature controllers: all you have to do is to set the desired temperature and the platen will start heating up. The closing force is set by means of the handpump and read out from the integrated pressure display.

Feel free to request a demo to see the presses and to find out more about their operation.

(3) Environmental aspects

The laboratory hot platen presses from Fontijne Presses do not only have a small physical footprint but also the economical footprint is low. Be pleasantly surprised about the low energy consumption and noise level. Our hydraulic system is designed without an accumulator. This means that the system is not constantly under pressure and that it can work with an on/off regulation: a motor of 0,7 kW is sufficient.

Moreover, the Fontijne Presses laboratory platen press is designed and in accordance with all ergonomic regulations as described in the ISO and CE regulation, for optimal and enjoyable use for every employee, and to avoid an impact on human health.

(4) Delivery time

The delivery time of a Fontijne Presses instrument depends on the press series. Typically, our LabManual and LabEcon presses have a shorter delivery time (2 to 8 weeks) than our LabPro series (16 weeks and up). This is because all LabPro presses are built to order.

(5) After-sales service

Our after-sales service starts as soon as the hydraulic laboratory platen press leaves our factory. Do you have questions about the connections or about the installation of the press? Would you like to know more about the software or how to operate the press? Are you interested in receiving an offer for preventive maintenance and calibration? Do you want to exchange a hydraulic filter or a relay?

Drop us an email at service@fontijnepresses.com to get in touch with our after-sales department. Either you will be supported by one of our service engineers, or you will be contacted by your local distributor or service partner.